菜单

DIN VDE 0282-6 H01N2-D Welding Cable

H01N2-D welding cable is used for transmission of high currents from the electric welding machine to the welding tool.

H01N2-D welding cable is highly flexible thus suitable for applications in the automobile industry, shipbuilding, transport and conveyor systems, tool making machinery, welding robots, etc.

H01N2-D welding cable retains high flexibility even under the influence of ozone, light, oxygen, protective gases, oil, and petrol.

It features cold resistant, UV resistant, flame retardant and highly flexible.So it is ideal for outside installation in dry, moist and wet areas.

Application

For use between the welding generator and the hand-electrode and the workpiece.

For use in the automobile industry, in shipbuilding, in transport and conveyor systems, tool making machinery, welding robots etc.

These cables retain their high flexibility even under influence of ozone, light, oxygen, protective gases, oil and petrol. The robust construction makes these cables resistant to both to cold and the heat as well as to flames. They are suitable for use in open spaces and in dry and damp conditions.

Standard

DIN VDE 0282-6 DIN EN 60228 class 5 (construction) HD 22.6

S2:1995+A1:1999+A2:2004

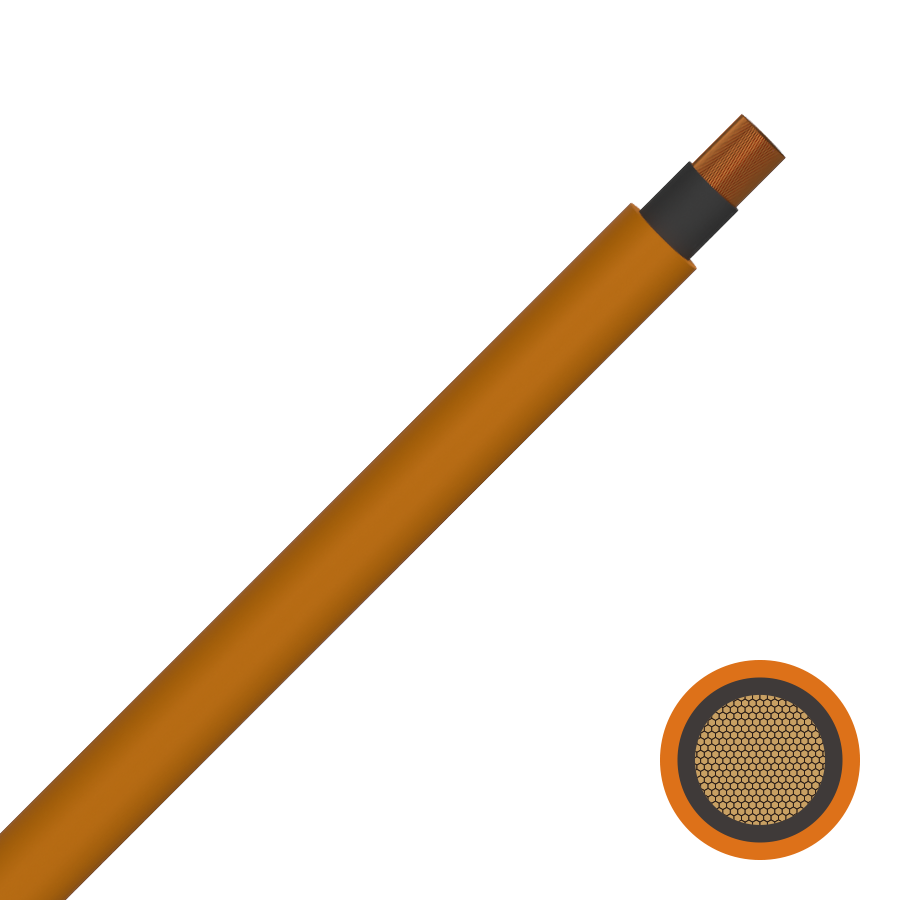

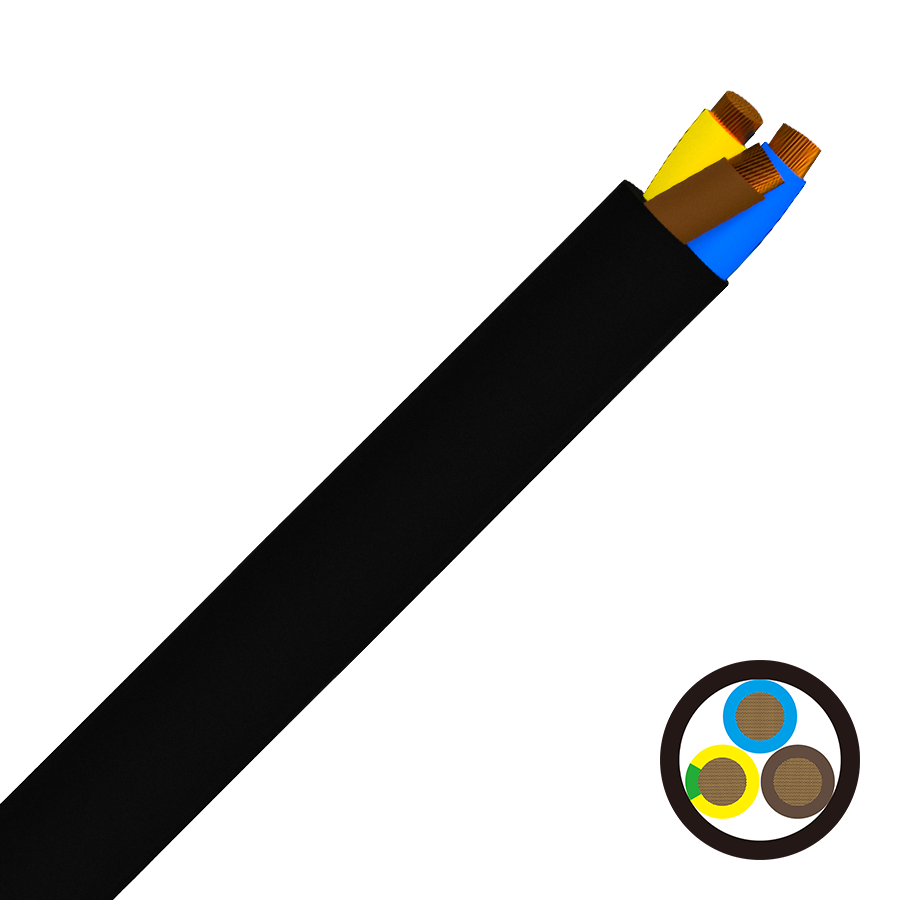

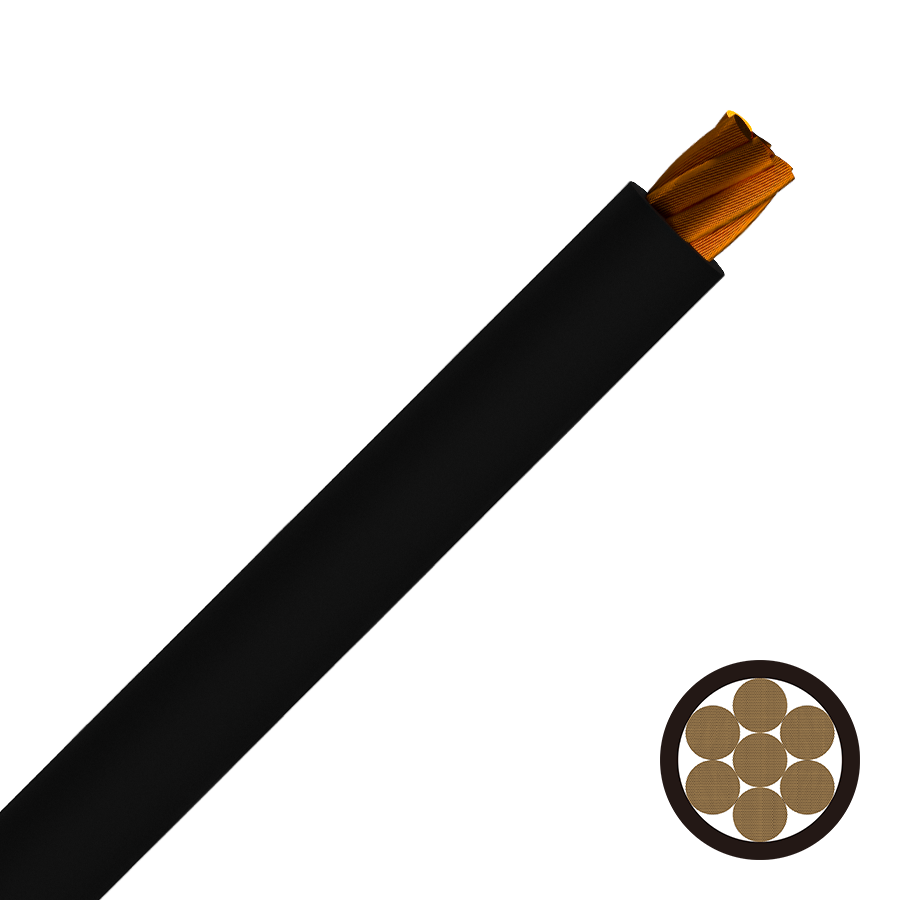

Construction

Conductor: extra flexible copper wire

Synthetic or paper separator over the core

Sheath: Polychloroprene rubber (neoprene) jacket EM5

Color of sheath: Black

Technical Characteristic

Working voltage: 100/100 volts

Test voltage: 1000 volts

Minimum bending radius:

12xOverall diameter (H01N2-D)

10xOverall diameter (H01N2-E)

Moving application operation temperature: -25℃ to +80℃

Fixed application operating temperature: -40℃ to +80℃

Flame retardant: IEC 60332-1

Technical Parameter

| Conductor Size/mm² | Sheath Thickne | Overall Diameter/mm | Max. Resistance at 20 ℃ | ||

|---|---|---|---|---|---|

| mm² | Wire NO./mm | ss/mm | MIN. | MAX. | Bare Copper |

| 10 | 320/0.20 | 2 | 7.7 | 9.7 | 1.91 |

| 16 | 512/0.20 | 2 | 8.8 | 11 | 1.16 |

| 25 | 800/0.20 | 2 | 10.1 | 12.7 | 0.758 |

| 35 | 1120/0.20 | 2 | 11.4 | 14.2 | 0.536 |

| 50 | 1600/0.20 | 2.2 | 13.2 | 16.5 | 0.379 |

| 70 | 2240/0.20 | 2.4 | 15.3 | 19.2 | 0.268 |

| 95 | 3024/0.20 | 2.6 | 17.1 | 21.4 | 0.198 |

| 120 | 614/0.51 | 2.8 | 19.2 | 24 | 0.157 |

| 150 | 765/0.51 | 3 | 21.2 | 26.4 | 0.125 |

| 185 | 944/0.51 | 3.2 | 23.1 | 28.9 | 0.102 |