菜单

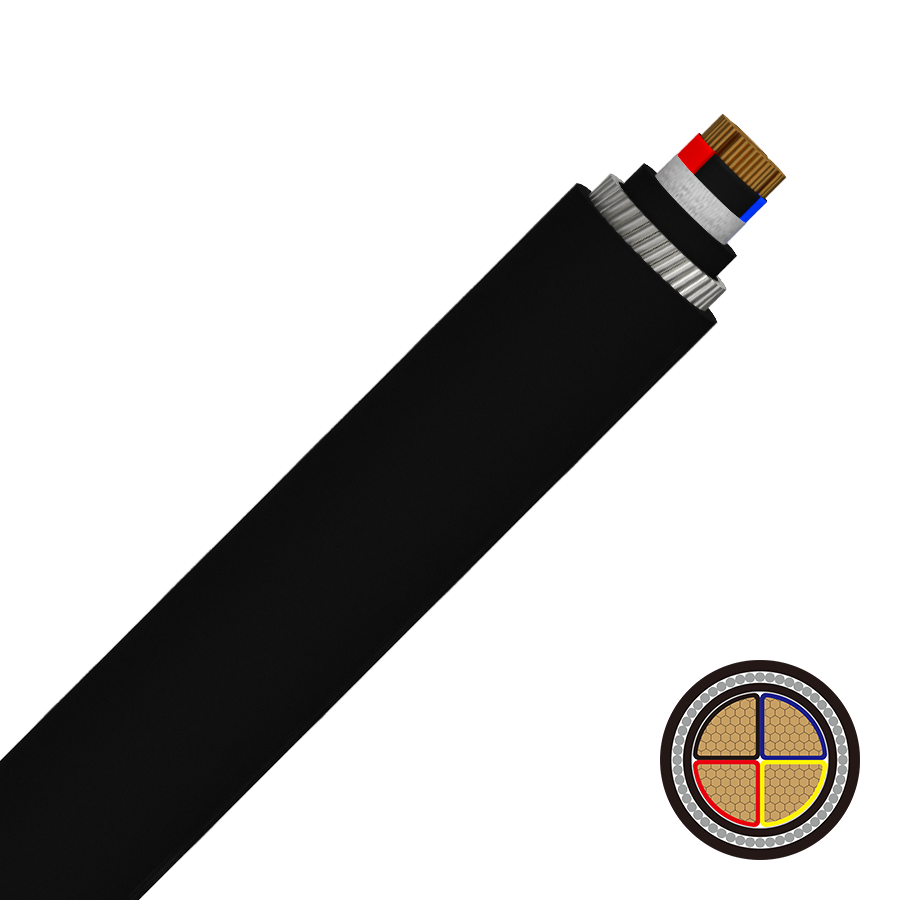

SANS 1507 Standard Low Voltage Power Cable

Used for direct burial power distribution applications in installation environments with free-draining soil conditions. They can also be installed internally.

We supply cables manufactured in accordance to SANS 1507-3 and SANS 1507-4 as part of our wide range of PVC insulated and XLPE insulated cables.

Application

LV Power Cable SANS 1507 To supply power to all types of fixed installations. suitable for use in ducts, racks and ladders as well as burial underground without further protection.

Standard

-SANS 1507-1 (Part 1):General – note to purchasers, guidance on the verification of the quality of extruded solid dielectric insulated cables, and guidance on the installation of extruded solid dielectric insulated cables

-SANS 1507-2 (Part 2):Wiring cables

-SANS 1507-3 (Part 3):PVC distribution cables

-SANS 1507-4 (Part 4):XLPE distribution cables

-SANS 1507-5 (Part 5):Halogen-free distribution cables

-SANS 1507-6 (Part 6):Service cables

Construction

Conductor: Conductor: class 1 solid , class 2 stranded copper conductor or aluminium conductor

Insulation: Polyvinyl Chloride (PVC)/XLPE

Armour method: Unarmored or Steel Wire Armour (SWA), Steel Tape Armour (STA), Aluminium Wire Armour (AWA), Aluminium Tape Armour (ATA), Steel Wire Armour+Tinned copper wire (SWA+ECC)

Sheath: Polyvinyl Chloride PVC

Technical Characteristic

Max.rated temperature of conductor: Nominal Operating 90℃.

short circuit:(Max.for 5 secs)250℃.

Temperature of laying, in air 25℃

Underground 15℃

For laying, single core, triangle laying for three cables.

Depth of laying in direct: 100cm

Coefficient of thermal resistivity of soil 100℃.cm/w

The cable can be laid without drop restriction, and the environment temperature shall not be lower than 0℃.

Single core, steel tape armoured cable should be only applied to direct-circuit line.

For nominal insulation thickness, size of armour,over-diameter,weight and current rating of flame-retardant

cable of class A, B,C,which should refer to the value of general cable.

Sheath colours: black with red stripe

Packing: 500m each drum or other length also available on request

Technical Parameter

| Size | Conductor | Insulation | Wrapping tape | Inner bedding | Armour | Sheath | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XLPE | Non-Woven | PVC | Galvanized steel wires | PVC | ||||||||||||||

| No | Shape Height | Shape Width | Min | Shape Height | Shape Width | Layer | Thickness | Dia | Thickness | Min. | Dia | No | Dia | Dia | Thickness | Min. | Dia | |

| 4×25 | 1 | 5.24 | 7.4 | 0.71 | 7.04 | 9.2 | 2 | 0.2 | 15.89 | 1.2 | 0.92 | 18.29 | 35±2 | 1.6 | 21.49 | 1.7 | 1.16 | 24.89 |

| 4×35 | 1 | 6.2 | 8.7 | 0.71 | 8 | 10.5 | 2 | 0.2 | 17.84 | 1.2 | 0.92 | 20.24 | 39±2 | 1.6 | 23.44 | 1.8 | 1.24 | 27.04 |

| 4×50 | 1 | 7.2 | 10.12 | 0.8 | 9.2 | 12.12 | 2 | 0.2 | 20.4 | 1.2 | 0.92 | 22.8 | 35±2 | 2 | 26.8 | 2 | 1.4 | 30.8 |

| 4×70 | 1 | 8.7 | 12.12 | 0.89 | 10.9 | 14.32 | 2 | 0.2 | 23.84 | 1.4 | 1.09 | 26.64 | 41±2 | 2 | 30.64 | 2 | 1.4 | 34.64 |

| 4×95 | 1 | 10.26 | 14.33 | 0.89 | 12.46 | 16.53 | 2 | 0.2 | 27.12 | 1.4 | 1.09 | 29.92 | 46±2 | 2 | 33.92 | 2.2 | 1.56 | 38.32 |

| 4×120 | 1 | 11.55 | 16.12 | 0.98 | 13.95 | 18.52 | 2 | 0.2 | 30.15 | 1.6 | 1.26 | 33.35 | 41±2 | 2.5 | 38.35 | 2.4 | 1.72 | 43.15 |

| 4×150 | 1 | 12.81 | 17.88 | 1.16 | 15.61 | 20.68 | 2 | 0.2 | 33.64 | 1.6 | 1.26 | 36.84 | 46±2 | 2.5 | 41.84 | 2.4 | 1.72 | 46.64 |

| 4×185 | 1 | 14.36 | 20.03 | 1.34 | 17.56 | 23.23 | 2 | 0.2 | 37.75 | 1.6 | 1.26 | 40.95 | 51±2 | 2.5 | 45.95 | 2.6 | 1.88 | 51.15 |

| 4×240 | 1 | 16.49 | 22.96 | 1.43 | 19.89 | 26.36 | 2 | 0.2 | 42.59 | 1.6 | 1.26 | 45.79 | 56±2 | 2.5 | 50.79 | 2.8 | 2.04 | 56.39 |

| 4×300 | 1 | 18.48 | 25.7 | 1.52 | 22.08 | 29.3 | 2 | 0.2 | 47.17 | 1.6 | 1.26 | 50.37 | 62±2 | 2.5 | 55.37 | 3 | 2.2 | 61.37 |